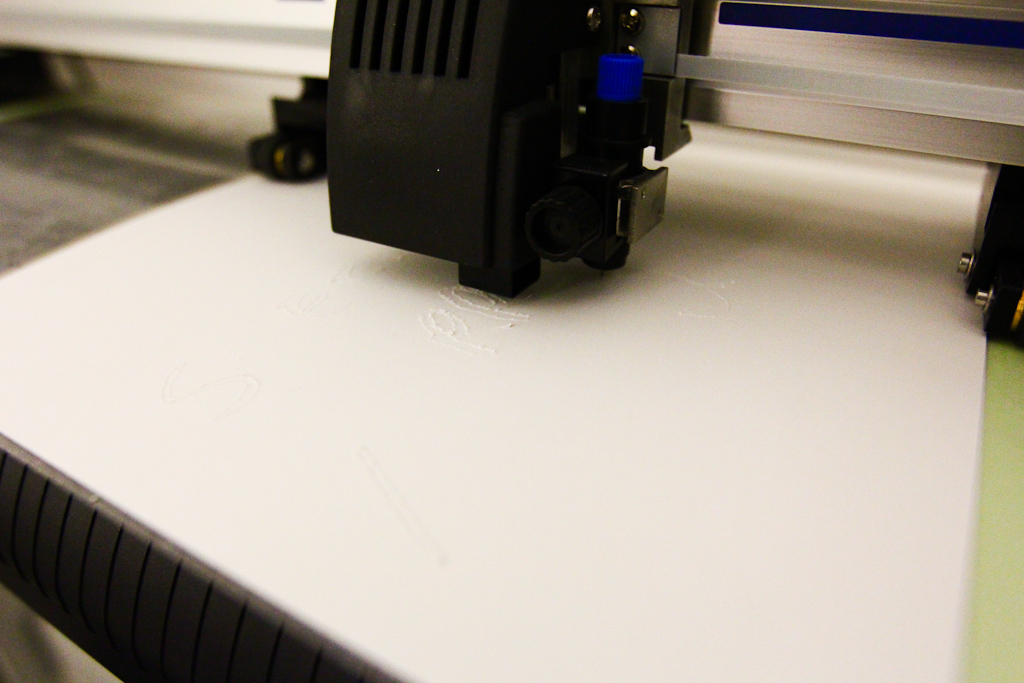

We’ll be picking up on this again today as we continue to experiment with cutting stencils of our handwriting on cardstock from our vinyl cutter, the Graphtec ce5000-60. These are very early tests, but will hopefully lay the groundwork for some processes and projects later on in the summer or fall.

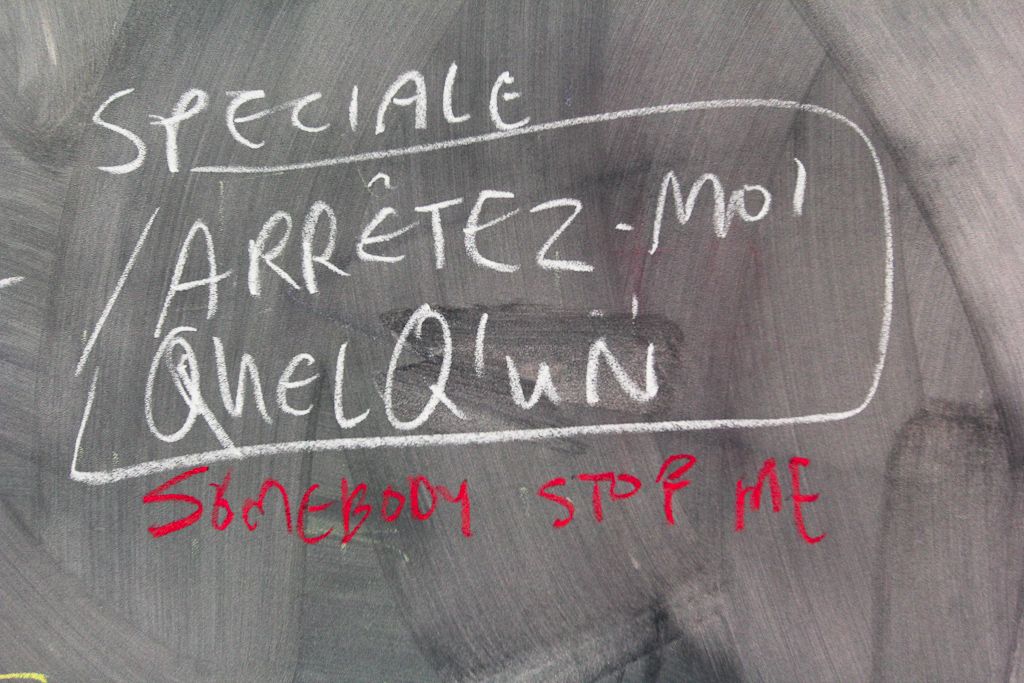

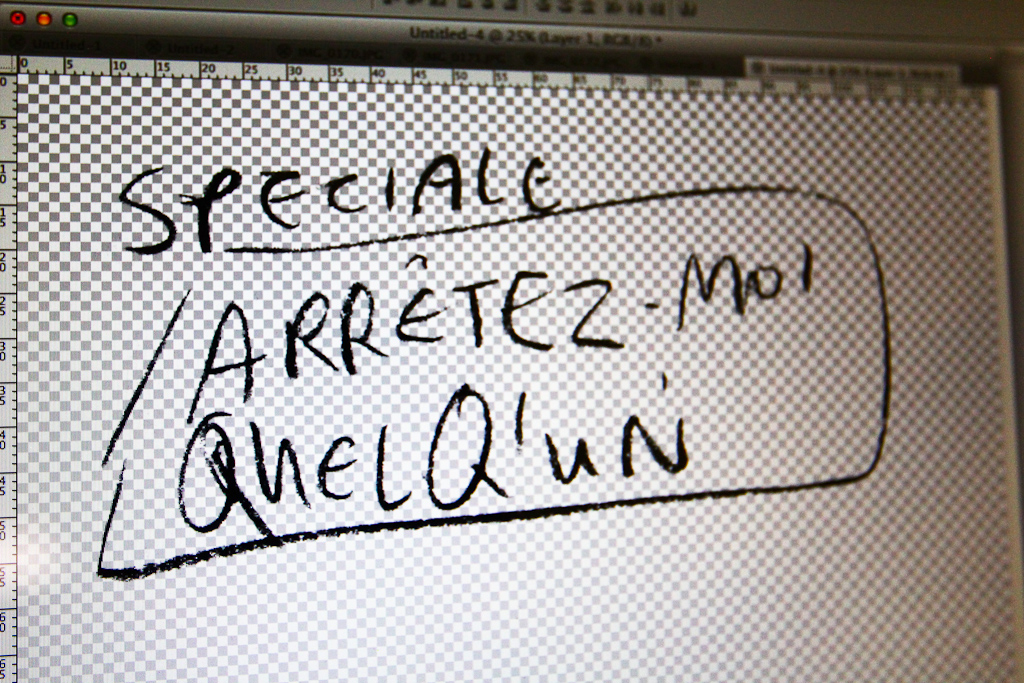

No big surprise, trying to convert writing on a chalkboard to a stencil produces a really challenging job for the cutter. The grain of the chalk was interesting to work into an outline / live trace in Illustrator. Also, Sara has nice handwriting.

Hiba’s handwriting worked a lot better on paper. We’ll almost certainly work from this as a starting point as we continue researching this.

But beyond handwriting, we’re also looking at a kind of automated process to turn photos into stencils — so the tests in cutting these kinds of very delicate edges have been worthwhile.

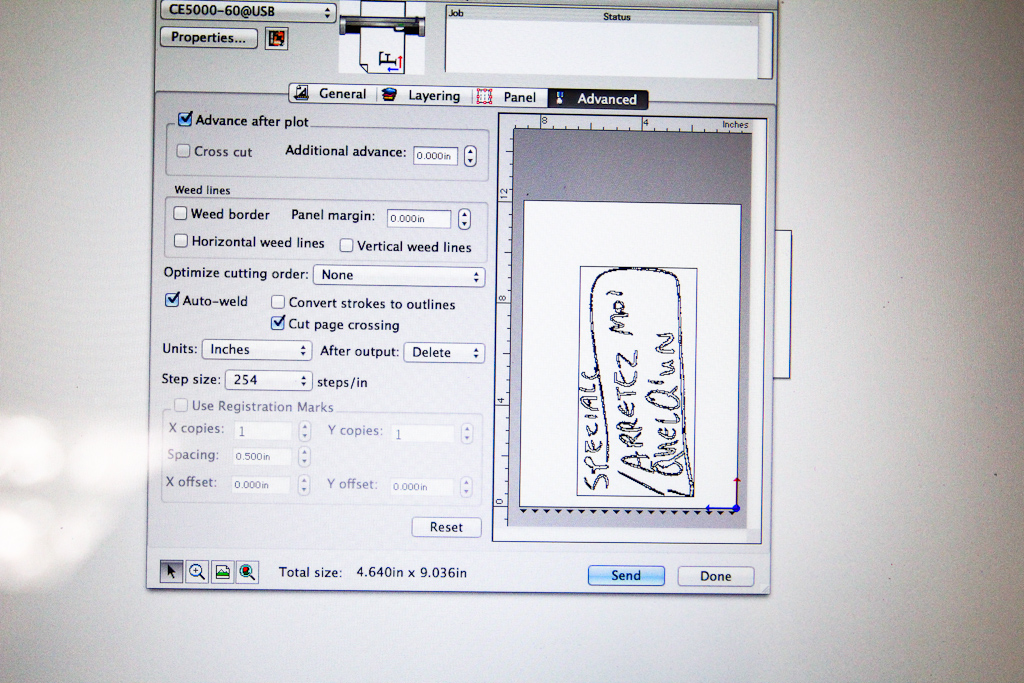

Above the cutting interface through Illustrator.

The adjusted image that we built the stencil file from — after live tracing in Illustrator.

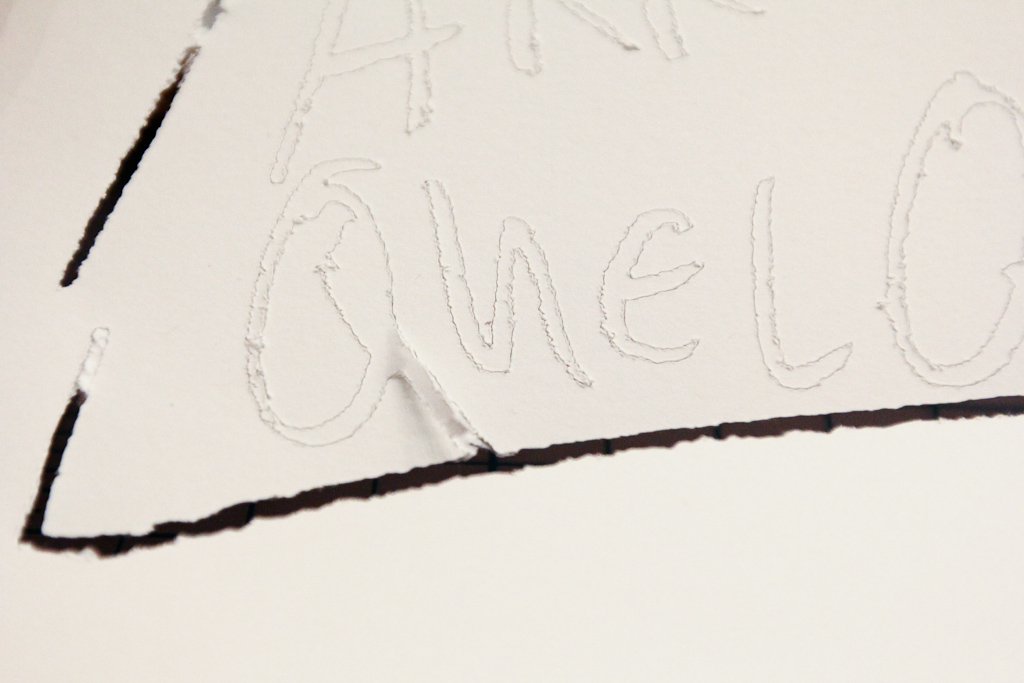

You can see the cutter did a pretty insanely great job at retaining the detail.

But, the blade didn’t quite make it through the paper entirely. So, we’ll have to make some adjustments on the down-force (I think that’s what it’s called) and try again. We used a similar process to cut the templates for our Letter Library from cardstock, but it’s entirely possible that the complexity of these cuts makes it more difficult for the blade to cut all the way through and maintain that depth of cut.

More later today and likely throughout the week …

I run the digital print shop in the Art Department at GVSU. We have a similar Graphtec machine and just went through the whole stencil cutting development. We purchased a special blade for cutting thicker material. http://www.advantagesignsupply.com/Graphtec-1-5-mm-Supersteel-30-Degree-Thick-Media-Cutting-Blade-2-Pack. We ended up offering cutting stencils from acetate or card stock. We’re glad to share anything we’ve learned.

hi Paul, thanks for this. Huge help, we’ll look into that blade.

We’ve been wondering about somewhat automating the process — any experience with that? We’ve messed around with a bunch of Photoshop actions to best prep the image for live-tracing in Illustrator with mixed results.

One main thing we found when using autotrace, is to use the pathfinder/unite function before doing any cutting. The unite function flattens the shapes to make them not be made up from overlapping lines and shapes. I don’t have any experience with automating the process, but I bet there is some kind of scripting possible.

Oh nice, good call with the unite function! Thanks!

I forgot to include the use of a “carrier sheet” This goes under the material that is being cut, and gives the cutter a material to cut through to without cutting into the graphtec bed, which would dull the (expensive) blades. http://www.graphtecamerica.com/FAQs/carrier_sheet.html has useful links. We purchased a carrier sheet, but have since theorized that a sheet of material of the appropriate thickness with a light, somewhat dry coating of spray mount would do just as well. We researched high-tech solutions, but then realized that the carrier sheets could pretty much be of any material and would not have to hold up in some special way.

Also, the deal with the special blade is mostly that it will reach the thickness needed while the standard vinyl blades will not. Also, they are designed to move powerfully through the thicker material.