Another day spent at 406 Pelissier. Working with these plastic bags is really time consuming, but it will be worth it. The projects we have in mind are taking longer than we may have initially aniticipated, but that’s been the case with everything we’ve ever done.

The banner is growing steadily, but we’re hoping for a final length of somewhere near 18 feet. We’ve also scouted a location, but we’re still working on the message for the banner itself.

Our continuing work with the planters is going well, as we’re about 1/3 of the way to the grand total of planters we’re hoping to make. Also, the test planter is doing well, with some wildflower seeds sprouting already. With the planter being indoors, it has certainly helped to keep the soil moist, but also (and as we had figured long ago), the first and second design iterations of the planters were drying the soil very quickly due to the use of newspapers. With the plastic bags, the soil seems to be holding moisture much better. We’ve been careful to create drainage holes, but we probably need to integrate this into the design more effectively.

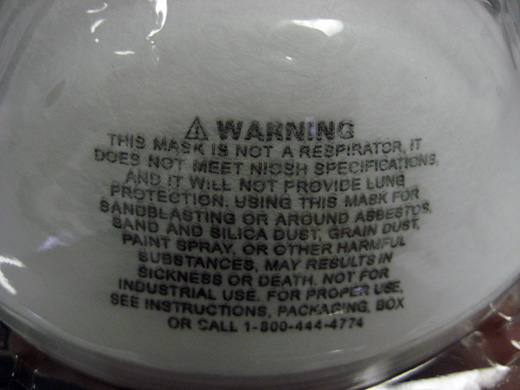

After Jodi’s comment, we decided to try out some masks.

However, as the warning indicates, these masks really aren’t going to save our lungs from whatever may be coming off the bags. However, something is probably better than nothing.

Steven was the first to don the mask.

Cristina, Steven, Danielle, Michelle, and Josh started setting up a work area.

Josh began to dig out the many plastic bags Steven brought.

We pulled out the rest of the plastic bags Steven brought last week and began to straighten them out. With more people, it made sense to try to be a bit more organized.

After an interview with the University of Windsor’s Daily News, Michelle did an interview in French with Radio Canada, which will air Thursday morning at 6:30am and then again at 7:45am. From what little French I could pick up, it sounded like the interviewer asked some good questions; Michelle said it went well and that they want to speak with her again later on in the summer!

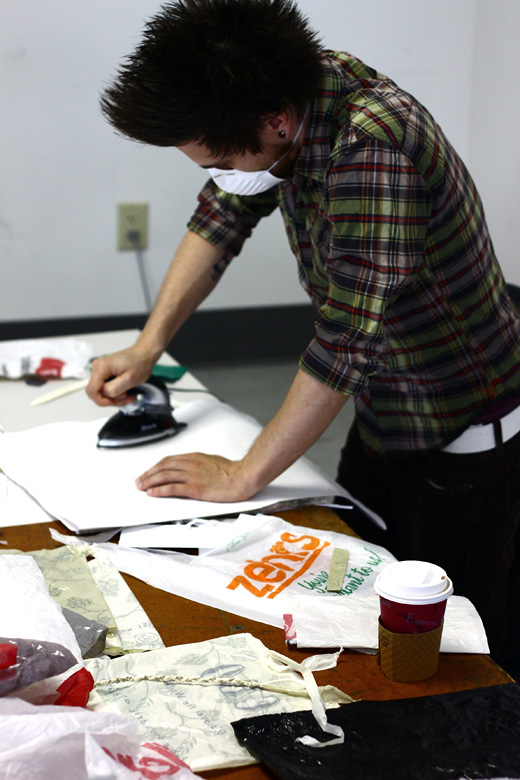

The iron heating up. The type of iron is ideal, as we discovered, the smaller irons or irons specifically designed for steaming, don’t really get hot enough.

I took my turn at cutting some plastic bags.

If you fold the bags over a couple times it’s a lot easier to cut. The reason we were cutting the handles off and the bottoms of the bags was to create a more uniform shape to start off with. All the scraps can be reused for other parts.

Josh gives the formal thumbs up (we missed you Josh).

The pile of plastic bags waiting to be cut, as Danielle begins working on her cutting skills.

Michelle moves the planters that we already finished from last week into another bag.

Josh folded the bags to hand off to Danielle to cut.

Danielle cut the bags, which were then handed off to Michelle and Cristina.

Michelle starts to fold a sheet of newly fused plastic into a planter shape.

I worked on another proposal, this time for Visual Fringe.

Steven kept busy with the banner, working to maintain some uniformity in the bags, as the red looked really good.

He also attempted some patching with other smaller bags, the Wonder bag above looked especially great.

Cristina using the little Shark iron, again, not the ideal tool as it’s really designed for steaming.

Danielle worked away on her thesis in between cutting and ironing.

Kiril stopped by to see the progress and get a tour. His submission was one of the ones selected for Text In-Transit.

The edge of the banner, layered plastic, multi-coloured.

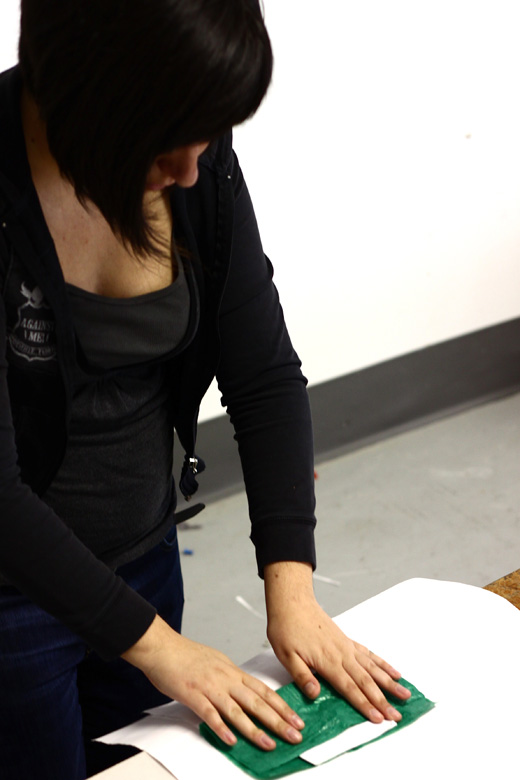

Cristina works on folding a planter using biodegradable green plastic bags. The biodegradability of these bags is sort of misleading though. The bags will biodegrade under the ideal conditions (most-often found in industrial composting situations), but they won’t begin to break down until they’re in that situation. This is fine for our project, as we don’t necessarily want the planters to biodegrade as long as they’re up and around the city, I just wanted to make that note in case anyone else wanted to use biodegradable plastic for some sort of fusing project.

Another planter in the making with a red Zellers bag.

Josh and I decided to wear the masks as we tried to make planters.

Josh had a good system going with the A&P bags—it helps to work continually with a bag of the same size, making things move along much faster.

He was trimming the edges too, which made his planters much more uniform.

My planters, on the other hand, weren’t nearly as uniform. The LCBO bags were by far the best to use though, I wish we had more.

Michelle stepped in to give me a hand with the folding.

Danielle kept working on her thesis.

I took over using the Shark, which I found especially frustrating. It took a long time to fuse the plastic bags, again due to the lack of intense heat.

Michelle worked on some labels for the planters.

We figured that since we’re now using plastic bags, we could use some basic mailing labels to stick on some information, as ink just rubs off when applied straight to the plastic. We didn’t try sharpies, but ultimately, I’m not sure handwriting the information we’re hoping to get onto the planters in practical.

Michelle also looked into a drawing/rendering of parts of a leaf to add something graphic to the label.

Josh shows off his mastered process of assembling a planter. These are the ideal size for using magnets, while the larger ones will likely require some other hanging technique.

The various plastics need different levels of heat, while Josh had figured out what A&P bags needed, I struggled to get something to work on a Zellers bag.

When ironing the bag between two layers of paper, it’s best to continually check to ensure that the bag is fusing, but also to double check that the bag isn’t melting.

Eventually I found a good mix of pressure and movement that seemed to fuse the bag.

My planters weren’t as well put together as what everyone else was doing, but hopefully they’re still useable.

The growing banner that Steven worked on all day.

This will eventually be the back, but the “HI!” and “BCL” are two examples of how we’ll end up writing on the banner.

Steven worked in columns, layering 3 or 4 bags, fusing them together and slowing building up sections that would be later attached to the rest of the banner.

Managing this banner is becoming increasingly unwieldy.

Cristina took over ironing for a while, again, the larger iron with more heat makes the process a lot easier.

Cristina and Josh have a good process going.

I moved on to fusing large black garbage bags, which we’ll use for the text.

The garbage bags are fused just once to give them enough rigidity to cut from.

Ideally, a larger iron set a bit below max heat would do this quickly.

Josh was rounding the edges of his planters, but the scraps below can be used for patches or for creating more loosely assembled planters.

Michelle finished up the label, as we started to wind down for the day.

Josh with the banner hanging above. We’ll be continuing with these projects over the next week or so, but we’re also starting to plan for the fall, with our anticipated new home.

doesn’t using plastic bags for the planters defeat the original purpose of using only biodegradable and natural materials? i applaud the group for trying to reuse material that would otherwise go into a landfill, but using it for planters that are meant to go out into the city seems sort of silly since you’ll just be putting more garbage out there (if the planter gets knocked down, etc). what are your thoughts on this?

The original idea of the planters was not in the interest of using biodegradable material, rather, it was in the interest of reusing Windsor’s discarded material to create an intervention.

The original planters were made out of old lance newspapers because a friend had accumulated a surplus, and thought we could effectively reuse them, their biodegradability was an advantageous plus. Of course those planters did not work out so well, so we moved onto resuing another discarded material, plastic bags.

Additionally, the focus of the project is about artistic interventions and suggestions for interventions within the city, and in this case it was about alternate locations for flora in the city.

While sustainability within our projects is considered, it is not our impetus. We are more interested in attempting to creatively generate dialogue (at least amongst ourselves) about the city and what it means to be an engaged citizen.

I don’t believe those masks will protect you from the vapors. They’re mostly for dust.

As Justin noted in the post, we were aware the masks were not optimal for blocking vapours (or whatever may be coming off the plastic as it fuses together), however they did eliminate some of the smell and we figured that some protection was probably better than none at all. As Jodi suggested (to much appreciation), ideally, we would be doing this in a more ventilated space, but we’re hoping that the size of the room combined with the fan in the ceiling vents and the open door helped mitigate it somewhat.

I know this is probably going against the point of this whole craft you’re working on, but I think it needs to be considered.

How much energy is being used to run these irons? Irons are pretty damn inefficient and use a good amount of juice, certainly factories set up specifically to make large plastic banners are a lot more efficient than a room of people with handheld irons trying to melt them all together. That doesn’t include the power to drive any ventilation fans, etc.

I’m guessing this project is about re-use, which is awesome. Don’t get me wrong at all..

But, as with all sustainable-message-art-stuff that’s being made lately, it seems like actual logic is being thrown out the window in exchange for the aesthetics of what people THINK sustainable and green products should actually look like and be made of.

But you do actually have to think about it… Surely you’d spend 100 times less energy making a banner if you just went to a construction site and asked them for an offcut of tyvex. Or, a company that makes banner advertisements for events to get their old banners once the event is done. Or an ad company that prints large ads on tyvex-like material. Or the ads on the sides of trucks that get swapped out and thrown away, etc. My point is there’s LARGE hunks of banner material being tossed all the time.

I was going to make a messenger bag for myself last year out of ironing plastic bags. I stole the idea from Make Magazine back in 2007 (http://blog.makezine.com/archive/2007/06/make_a_messenger_bag_out_1.html).. but I didn’t want to die of plastic chemical death. I also realized that all my plastic bags go to use anyways as trash bags, so I’d actually have to get MORE bags just to use for the project, which negates the whole recycling thing. Eventually some friends scored a huge tyvex advertisement, and now we all have more than a lifetime supply of rugged plasticy material! I’d give ya tons if was there.

Also yeah, as Darren said, those are particulate masks.. good for wood dust. 100% useless for chemicals that come off burning plastic. I’d advise you to go buy good masks, but you’d spend more money on the masks than it’d cost to buy lots and lots and lots of banner material :)

There are absolutely issues regarding the amount of energy we’re using, I’m sure. Likely, we are using more energy than it would take to ever get anything banner-like put together from tyvek material, or from actually getting a banner donated from a print shop somewhere. And of course, these plastic bags would have likely been used for something else anyways (whether for small garbage bags, or for carrying something else, etc.), but we didn’t set out to solely try to divert waste from the garbage dump. We had projects in mind that seemed fitting to use this material / technique, which as you point out Mike has been used by many, many, many people before us, and the aesthetic of the fused bags was interesting to us, as artists, so it seemed like a good next step in our research on the planter project (the banner has been another project idea that came from working with these materials).

Working with these materials hasn’t been about trying to create the sustainable-message-art-stuff you mentioned, but rather about attempting to explore materials that were new to us and learning something from that, and certainly part of that learning process has been about the issues surrounding the fusing of the plastic and the resources required to do that. This is not to try to excuse ourselves for using the energy required to power the irons or using the plastic bags in the first place, but just to clarify, that we didn’t set out to make a project that necessarily became a closed-loop sustainable initiative. The projects that have been developed through working with these plastic bags have been with ideas of creative interventions in mind, and have come out of past research (and materials), and may in turn lead us into other projects and other ideas, which will certainly use other materials.

For sure, and I absolutely see your point. It’s always fun to just play around with different materials and see what you can and can’t do with them. As you said, it leads to new uses.

I’m just cautioning and ranting to not fall into the trap (that a lot of people fall into) of using terms like “sustainable”, “adaptive reuse”, “recycled”, and “green” to sell or justify things that aren’t actually proven to be any of those things. Just because it has the appearance that it’s less energy/waste/pollution, etc.. doesn’t mean it actually is! And stay safe when experimenting with different materials..